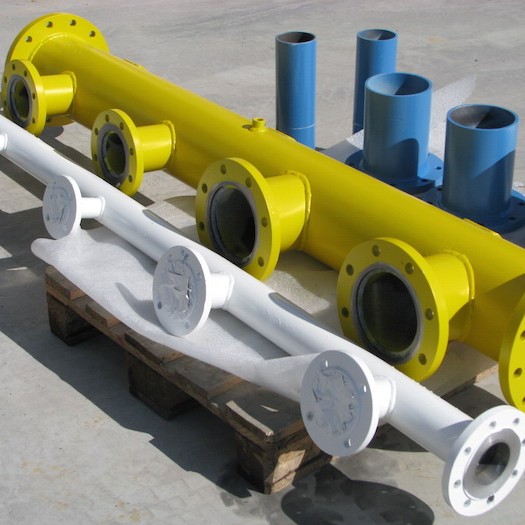

PIPING

AFP has always specialized in the production of piping systems, including high-pressure and large diameter pipes.

The production program includes the purchase of materials, the preparation of technical documentation (MDR manufacturer data report), the prefabrication of pipes in the workshop or at the customer’s site, the welding and assembly including tools and valves

Metal materials used: carbon steel, AISI 304, AISI 316L, AISI 321, AISI 904L, SAF 2205, SAF 2507, 254 SMO, Hastelloy, titanium and nickel.

Plastic materials: PP, PVC-C, PVC-U, PVDF, HDPE

The constructions will be carried out according to standards EN 13445-3 (dir. 97/23 / CE-PED) or according to ASME IX and ASME VIII..

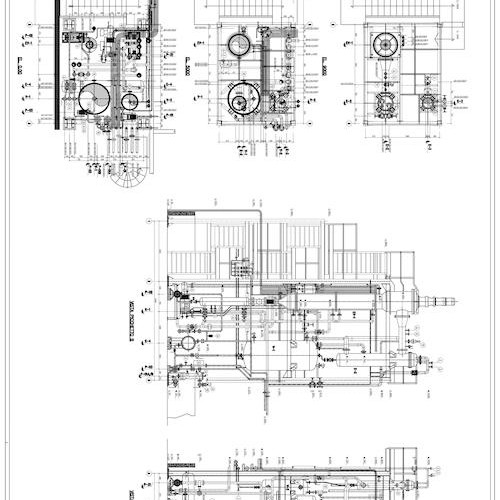

DETAIL ENGINEERING

If requested by a client, AFP can independently carry out the detail engineering of the system: layout, piping diagram, isometric drawings for piping, bills of materials, specifications, line class.

METAL STRUCTURES

AFP produces support structures for installations, skids, pipe racks, safety staircases, mezzanines, walkways, in both carbon steel or stainless steel and other metal fabrications. The production, if requested, can include the design, drawing and calculation report for any structures, according to EN 1090.

SKID

AFP produces skids on your own premises, from small to major sizes.

The production plan involves the assembly of the base or support structure, the mounting of the equipment, production of the piping and clamping connections, the assembly of valves and instrumentation and testing.

PRESSURE EQUIPMENT

AFP designs, calculates and drafts the construction drawings of pressure equipment

It manufactures atmospheric equipment: carbon steel tanks, AISI 304, AISI 316L, AISI 321, AISI 904L, SAF 2205, SAF 2507, 254 SMO, Hastelloy, Titanium

It manufactures pressure vessels (PED): tanks, carbon steel exchangers, AISI 304, AISI 316L, AISI 321, AISI 904L, SAF 2205, SAF 2507, 254 SMO, Hastelloy, Titanium

It manufactures large storage tanks, with flat bottom and conical roof installed.

PLANT INSTALLATIONS

AFP carries out the installation of industrial plants, positioning of equipment, heat exchangers, tanks, the installation and connection of pipes and valves.

AFP is qualified in the installation of heating systems, gas and fire extinguishing pipelines and fire extinguishing installations.

MAINTENANCE

AFP has, within its organization, specialist personnel for the extraordinary maintenance of production plants, in particular regarding: the dismounting and reassembling of plant components (tanks, reactors, heat exchangers, etc.), the replacement/modification of piping and metal structures.

SERVICE – REPAIR OF EQUIPMENT

The service plan provides for timely interventions in order to limit production stoppage when repairing pressure equipment.

The services are divided into:

Authorized instruction procedures INAIL for production modifications on constructions, calculations of pressure and temperature tests, welding repair work carried out according to EN or ASME.

SURFACE TREATMENT, INSULATION, NDT CONTROLS

In order to offer a complete plant construction service, AFP uses a chain of qualified subcontractors for varnishing pipes, metal fabrications, hot dip galvanizing, the execution of non-destructive testing such as x-rays, ultrasound, magnetic particle and liquid penetration controls.

Maximum availability and flexibility on the part of all the AFP offices guarantee a reliable and professional relationship with customers and suppliers.